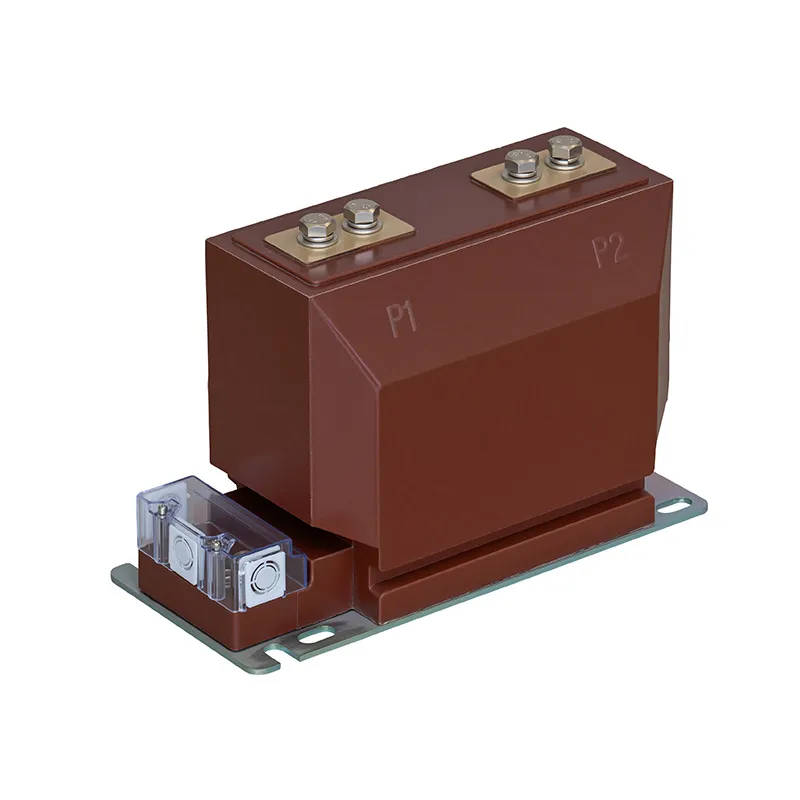

Description

The JDZX10-10 Voltage Transformer is a single-phase, epoxy-cast transformer equipped with a residual voltage winding. It is ideal for 10kV power systems operating at 50Hz or 60Hz and is widely used for voltage measurement, energy metering, and relay protection applications.

Model Meaning

-

J – Voltage Transformer

-

D – Single-phase

-

Z – Epoxy-cast insulation

-

X – With residual voltage winding

-

10 – Design number

-

10 – Rated voltage (10kV)

Technical Specifications

-

Primary Voltage: 10kV

-

Secondary Voltage: 100V (standard)

-

Residual Voltage Winding: 100/3V

-

Frequency: 50Hz or 60Hz

-

Accuracy Classes & Rated Capacity:

-

0.2 – 50–100VA (high-precision metering)

-

0.5 – 100–200VA (general measurement)

-

3 – 200–400VA (relay protection)

-

-

Insulation Levels:

-

Primary-to-ground: 12/42/75kV (rated voltage / short-time withstand / lightning impulse)

-

Secondary-to-ground: 3kV, 1 min

-

Structural Features

-

Compact & Durable: Single-phase, epoxy-cast structure offers moisture, dust, and corrosion resistance.

-

Winding Design: High-strength insulated primary winding; secondary and residual windings are fully isolated for accuracy and reliability.

-

Housing: Smooth, weather-resistant epoxy resin shell for long-term durability.

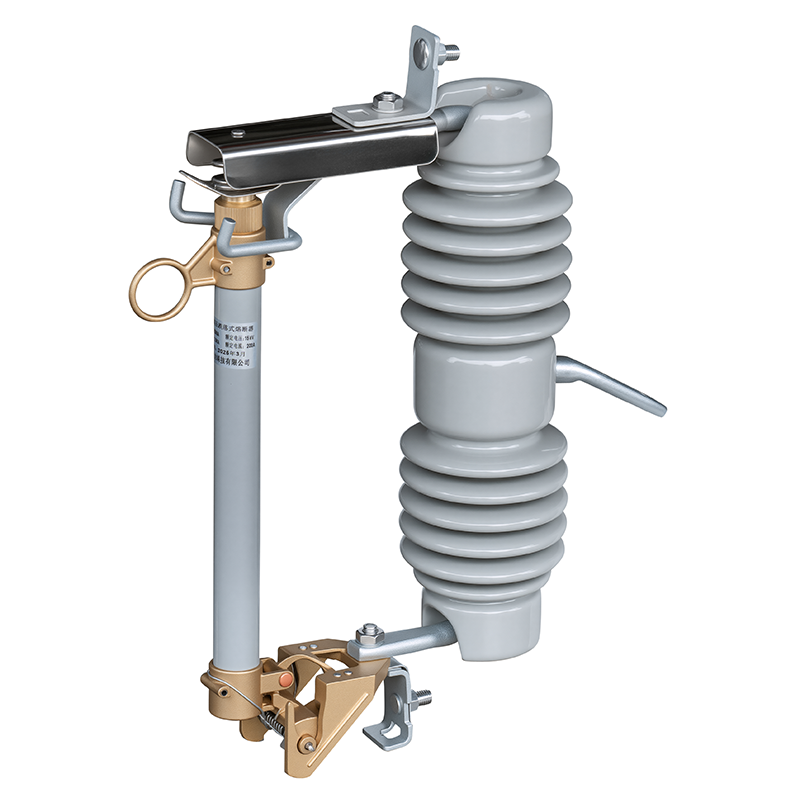

Installation & Usage

-

Inspect for physical damage and verify nameplate parameters.

-

Measure insulation resistance: primary ≥ 1000MΩ, secondary ≥ 10MΩ.

-

Can be installed inside switchgear or on a dedicated mounting bracket.

-

Ensure secure mounting with correct alignment; connect high-voltage and secondary circuits properly.

-

Do not short-circuit secondary winding; residual voltage winding must be grounded during normal operation.

-

Perform regular operational checks and preventive tests (insulation resistance, dielectric loss, voltage withstand).

Maintenance & Inspection

-

Daily: Clean surface, tighten terminals, check secondary circuit fuses.

-

Routine Inspection: Every 3–5 years for full maintenance including visual inspection and electrical testing.

-

Replace damaged components and verify performance.

Transportation & Storage

-

Avoid severe vibration, collision, and inversion during transport; use proper packaging.

-

Store indoors in a dry, ventilated area at -25°C to +40°C with humidity below 85%.

-

Periodically inspect appearance and insulation condition during storage.

Request a Quote Now

Our team will get back to you within 24 hours.