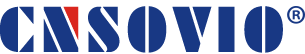

The RW12 High Voltage Fuse is commonly used in outdoor electrical systems for overload and short-circuit protection. It is suitable for power transformers, power lines, and other 10kV or lower AC 50Hz systems. Its compact design, cost-effectiveness, and easy maintenance make it an ideal solution for reliable electrical protection.

Structure

- Fuse Tube: The core component containing a metal fuse wire (copper or silver) and quartz sand. The fuse wire melts under overload or short-circuit conditions, while quartz sand suppresses arcs and dissipates heat.

- Contacts: High-quality copper alloy contacts ensure excellent conductivity and secure connection between the fuse and the circuit.

- Insulator: Ceramic insulators provide mechanical strength and electrical insulation, supporting the fuse tube and contacts safely.

- Operating Ring: Mounted on top of the fuse tube for easy operation during switching.

Technical Specifications

- Rated Voltage: 10kV, suitable for most 10kV power systems.

- Rated Current: 2A to 100A options to match different circuit load requirements.

- Breaking Capacity: Up to 50kA at rated voltage.

- Time-Current Characteristics: Melting time decreases as current increases (refer to product curve).

- Power Frequency Withstand Voltage: 42kV for 1 minute.

- Lightning Impulse Withstand Voltage: 75kV for effective lightning protection.

Working Principle

Under normal operation, the fuse wire carries the rated current without interruption. When an overload or short-circuit occurs, the fuse wire heats up and melts, generating an arc inside the fuse tube. Quartz sand quickly extinguishes the arc, cutting off the circuit to protect equipment and lines.

Installation & Usage

- Check the fuse and its parts for damage and confirm correct specifications.

- Install supports, insulators, contacts, and fuse tube securely.

- Connect the fuse to the circuit with firm, reliable connections.

- Always follow safety procedures when replacing fuse tubes and performing inspections.

Maintenance

- Daily: Inspect the fuse for dust, damage, and loose contacts.

- Quarterly: Perform a full inspection, checking contact wear and insulation.

- Annual: Conduct preventive tests such as insulation resistance and withstand voltage tests.

- Replace blown fuse tubes only after addressing the cause of the fault.

Storage & Transportation

- Transport upright with protective packaging to prevent shocks and damage.

- Store in dry, ventilated indoor spaces at -25°C to +55°C and <85% relative humidity.

- Avoid exposure to corrosive substances and inspect periodically during long-term storage.

Safety Warnings

- Only qualified personnel should operate or maintain the fuse.

- Keep unauthorized personnel away and display clear warning signs.

- Wear proper protective equipment such as insulated gloves and shoes during handling.

Request a Quote Now

Our team will get back to you within 24 hours.