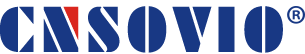

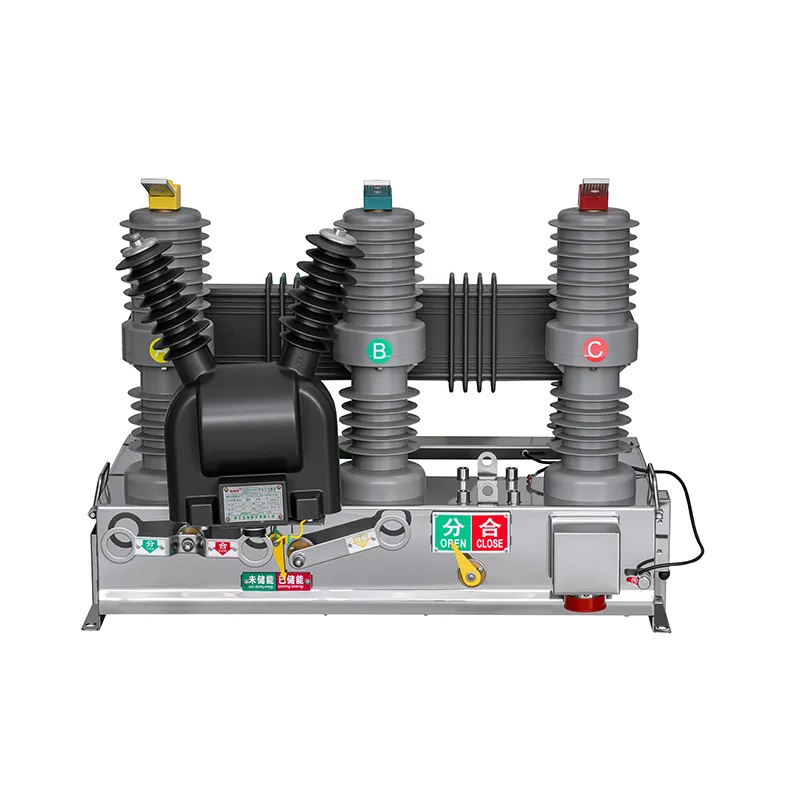

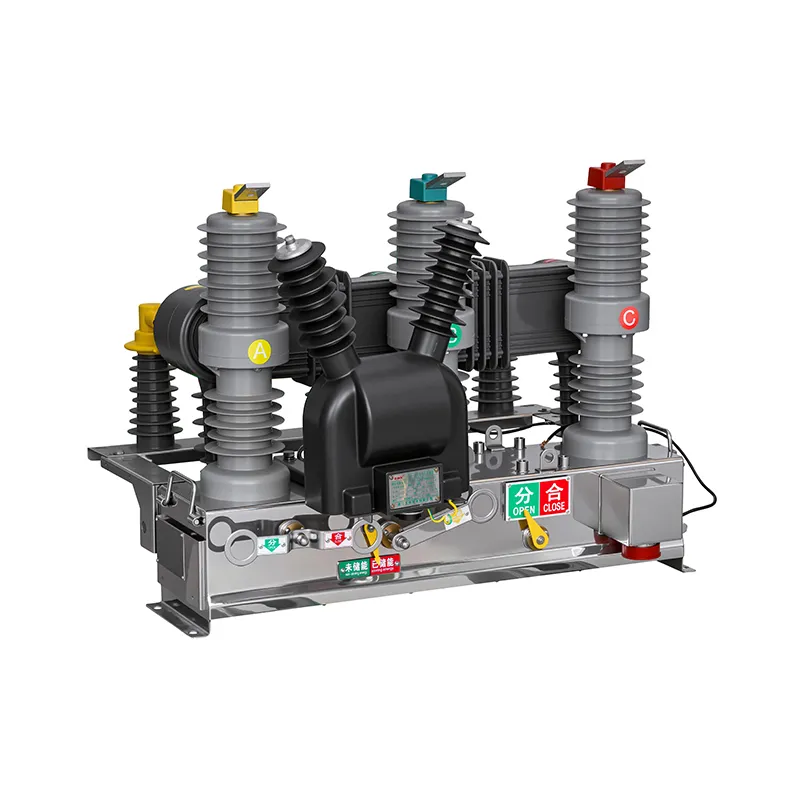

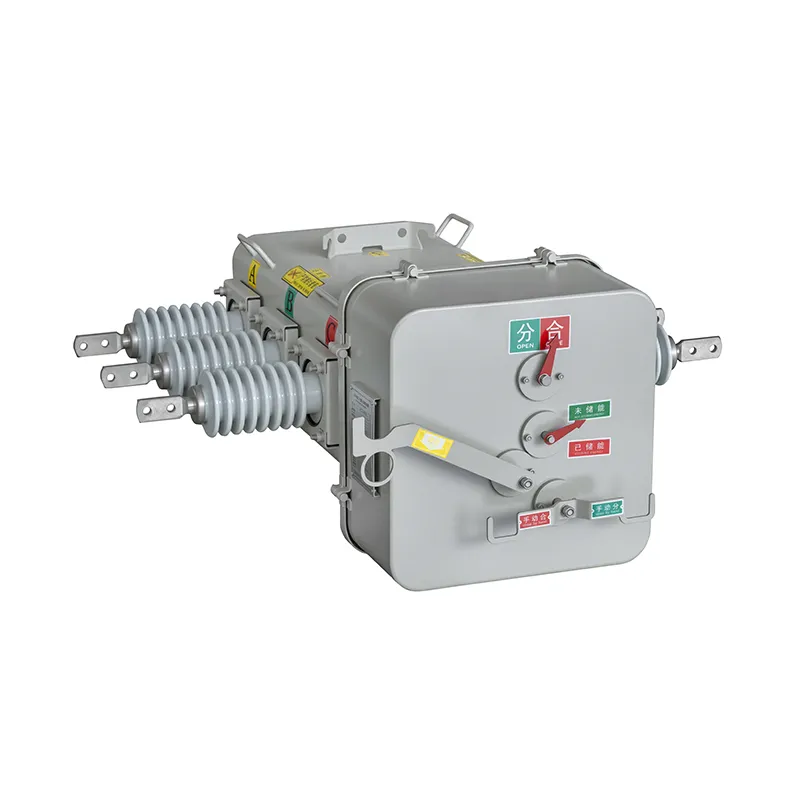

(1) Product Definition

An Intelligent Vacuum Circuit Breaker (IVCB) is an advanced switching device that combines modern electronics, computer technology, and communication systems with a traditional vacuum circuit breaker. It uses vacuum as both the arc-extinguishing and insulating medium, and integrates a smart control unit for precise control and monitoring.

It is widely used in power transmission and distribution networks, industrial facilities, and commercial buildings to control and protect electrical circuits, ensuring safe and stable operation of power systems.

(2) Product Features

Excellent Arc-Extinguishing Performance – The vacuum medium offers superior insulation and arc-quenching capabilities. Arcs are extinguished quickly during disconnection, with minimal energy and contact wear, extending service life and breaking capacity.

High Intelligence Level – Equipped with a smart control unit for real-time monitoring of operating status and electrical parameters (voltage, current, power, etc.). It can automatically execute switching operations based on preset protection strategies, enabling quick fault detection and response.

Reliable Operation – Advanced mechanisms and control technology ensure precise switching times and prevent misoperation or failure to operate, improving system reliability.

Low Maintenance – Minimal contact wear and stable arc-extinguishing performance mean longer maintenance intervals, reduced workload, and lower maintenance costs.

Environmentally Friendly & Energy Efficient – The vacuum medium is free from harmful gases, producing no pollution. Low operational energy consumption meets environmental protection and energy-saving requirements.

2. Technical Specifications

(1) Basic Parameters

| Parameter | Value |

|---|---|

| Rated Voltage | 6kV, 10kV, 35kV (customizable) |

| Rated Current | 200A, 400A, 630A, 1250A, 2000A (customizable) |

| Rated Short-Circuit Breaking Current | 6.3kA, 12.5kA, 16kA, 20kA, 25kA, 31.5kA (customizable) |

| Rated Short-Circuit Making Current | 16kA, 31.5kA, 40kA, 50kA, 63kA (customizable) |

| Rated Frequency | 50Hz or 60Hz |

| Contact Gap | 6–10kV: 8–12mm / 35kV: 30–40mm |

| Contact Stroke | 6–10kV: 2–4mm / 35kV: 4–6mm |

| Opening Time | ≤0.06s |

| Closing Time | ≤0.12s |

| Mechanical Life | ≥10,000 operations |

| Electrical Life | 1,000–5,000 operations (depending on rated short-circuit capacity) |

(2) Insulation Parameters

| Parameter | Value |

|---|---|

| 1 min Power Frequency Withstand Voltage | 6–10kV: 42kV / 35kV: 95kV |

| Lightning Impulse Withstand Voltage | 6–10kV: 75kV / 35kV: 185kV |

| Protection Level | IP30 or higher (customizable) |

(3) Mechanism Parameters

| Parameter | Value |

|---|---|

| Mechanism Type | Spring Operating Mechanism / Permanent Magnet Mechanism |

| Motor Power | 0.5–2kW (depending on type) |

| Energy Storage Time | ≤15s |

3. Main Components

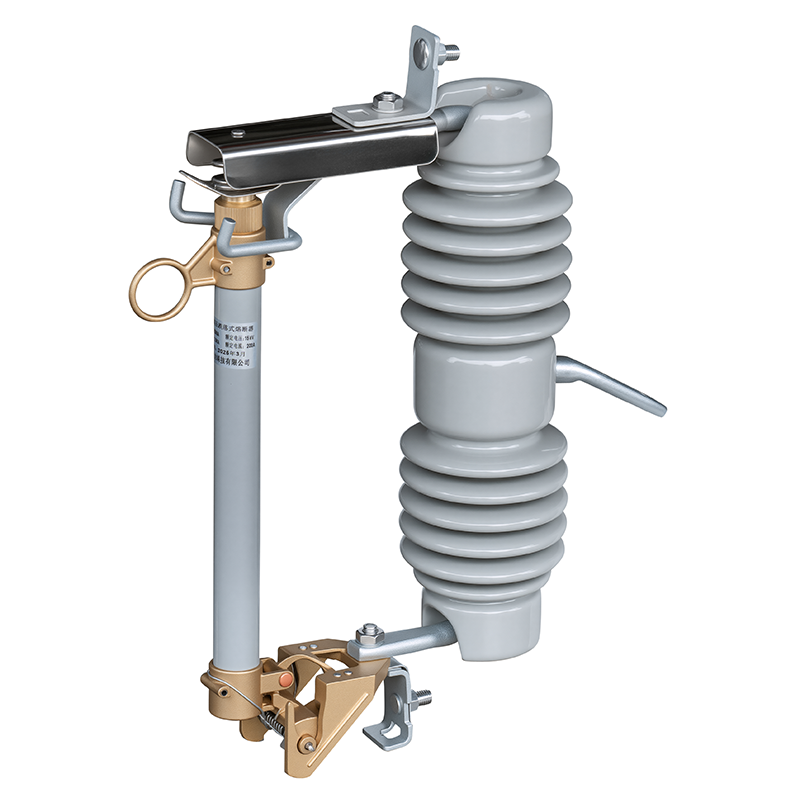

Vacuum Interrupter – The core component consisting of moving and fixed contacts, a shield, and a bellows. Copper-chromium contacts ensure excellent conductivity and anti-welding performance. The shield absorbs arc energy, while the bellows allows contact movement and maintains vacuum.

Operating Mechanism

Spring Mechanism – Stores energy via a motor and releases it through cams and latches for reliable operation.

Permanent Magnet Mechanism – Uses a permanent magnet to maintain positions, switching via electromagnetic coil control. Simple structure, low power consumption.

Smart Control Unit – Includes a microprocessor, sensors, and a communication module for data collection, analysis, protection control, and remote operation.

Enclosure & Accessories – Durable housing (metal/plastic), current transformers, voltage transformers, operation indicators, and energy storage indicators.

4. Installation & Commissioning

Preparation:

Check model/specifications and ensure no damage.

Prepare tools (wrenches, screwdrivers, level, grounding straps).

Install in a dry, ventilated, vibration-free, non-corrosive location.

Installation Steps:

Foundation Installation – Install base channels/supports with level accuracy ≤5mm/m.

Breaker Mounting – Lift into place and secure with bolts, ensuring vertical tolerance ≤1.5mm/m.

Electrical Connections – Connect incoming/outgoing cables per wiring diagram; ensure correct phase sequence and grounding.

Grounding – Ensure grounding resistance ≤4Ω.

Commissioning:

Perform insulation resistance tests.

Conduct withstand voltage tests per standards.

Test operating mechanism timing and synchronization.

Configure and test smart control functions and protection accuracy.

5. Operation

Manual Operation – Use the handle for on-site switching (power off first).

Electric Operation – Use control buttons or remote commands, ensuring the mechanism is charged before operation.

Automatic Protection – Smart control unit detects faults and executes trip commands for protections such as overcurrent, overvoltage, undervoltage, and earth fault.

6. Maintenance & Troubleshooting

Routine Maintenance:

Keep the exterior clean.

Tighten loose bolts.

Check operation indicators and counters.

Monitor control unit indicators and communication status.

Periodic Inspection:

Every 1–2 years: Test vacuum level, inspect mechanisms, lubricate, calibrate controls.

Every 3–5 years: Measure contact resistance and travel, replace if worn beyond limits.

Common Faults:

Switching Failure – Check mechanism, wiring, and contacts.

False Tripping – Verify settings and sensor health.

Communication Failure – Check module, cables, and protocol configuration.

7. Transport & Storage

Transport:

Use appropriate lifting/transport equipment.

Protect vacuum interrupters with proper packaging.

Keep away from rain, moisture, and sunlight.

Storage:

Store in a dry, ventilated place at -25°C to +55°C, ≤95% humidity.

Keep upright to avoid internal damage.

Inspect periodically for rust or moisture signs.

8. Safety Precautions

Follow electrical safety rules, wear PPE (insulating gloves, shoes, etc.).

Never touch live parts during operation.

Disconnect power and ground before maintenance.

Avoid operation during thunderstorms.

During high-voltage tests, use supervision and insulated mats.

Request a Quote Now

Our team will get back to you within 24 hours.