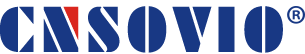

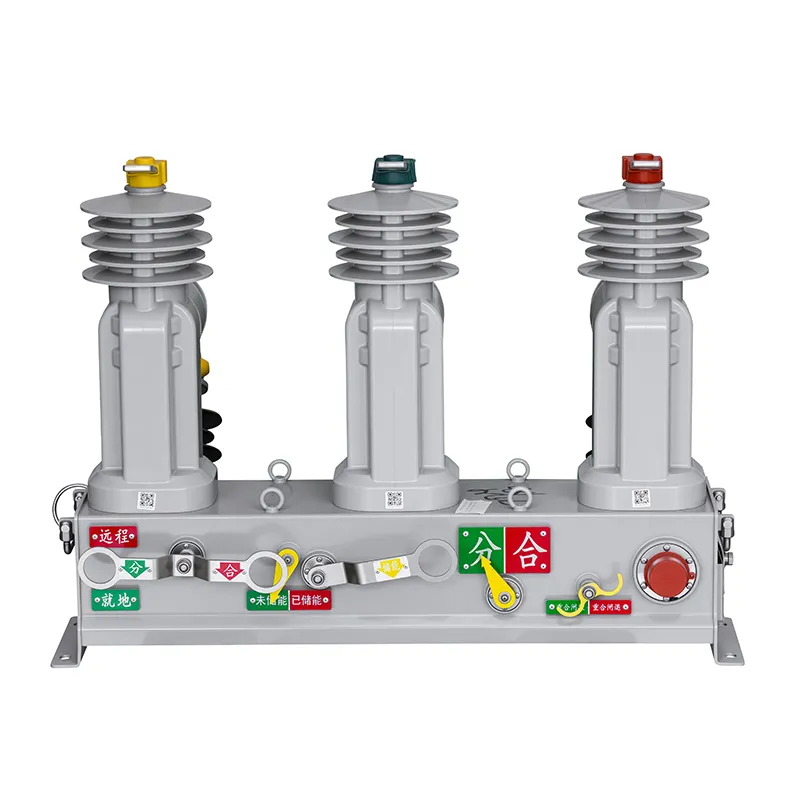

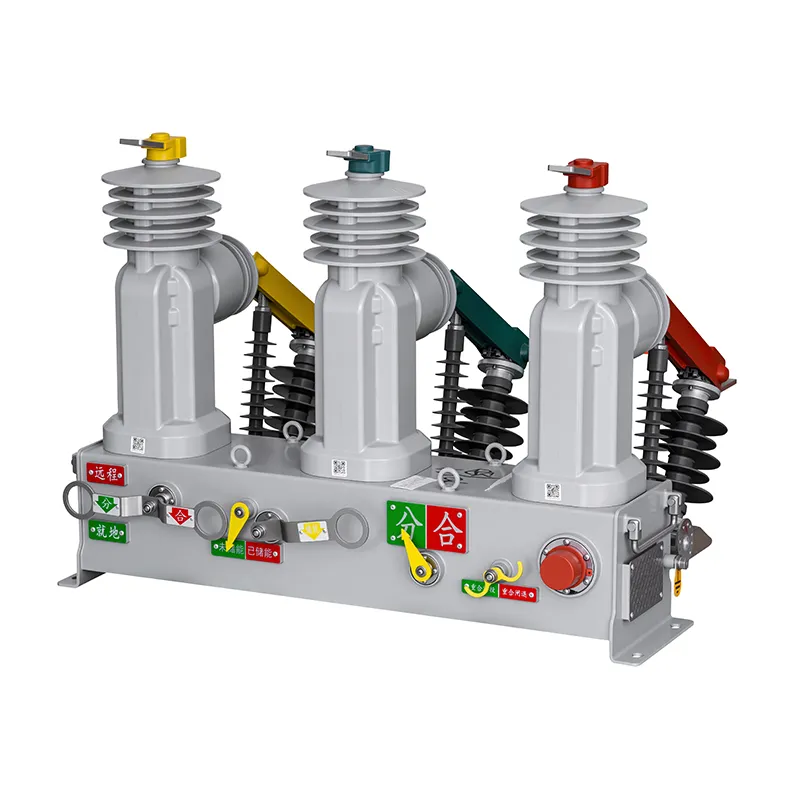

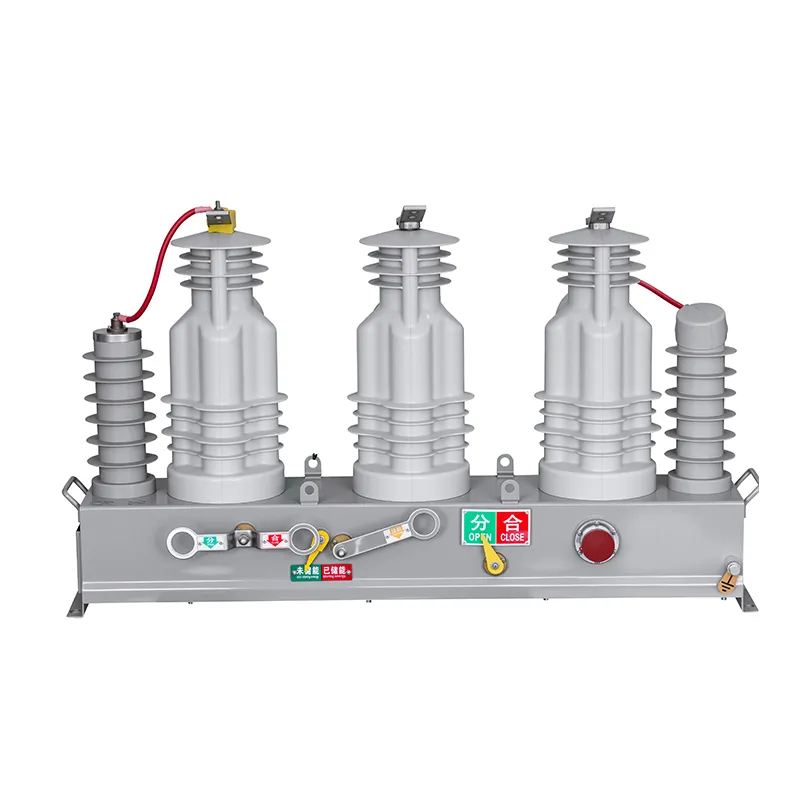

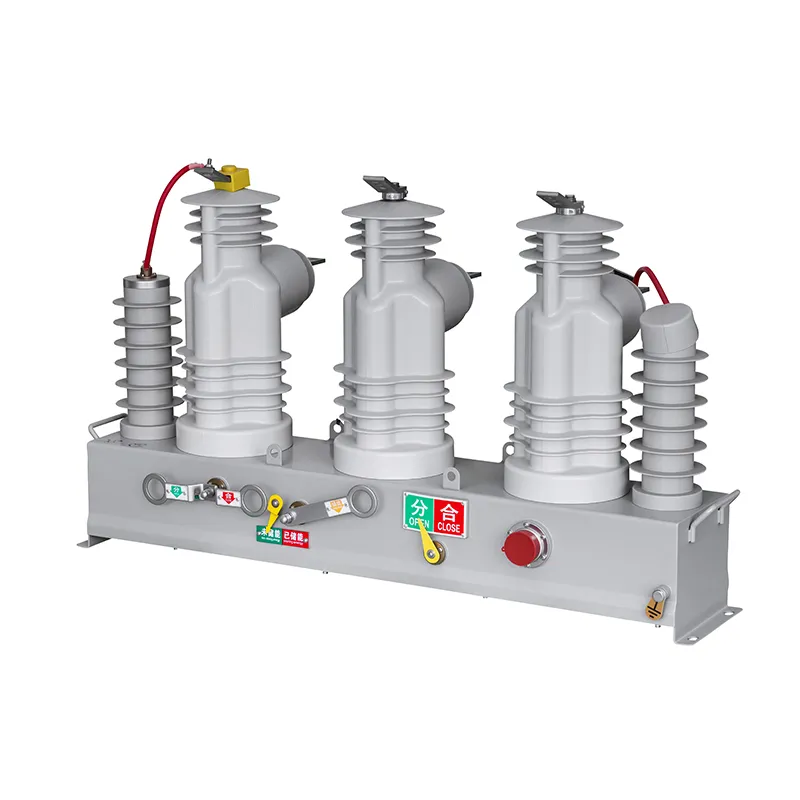

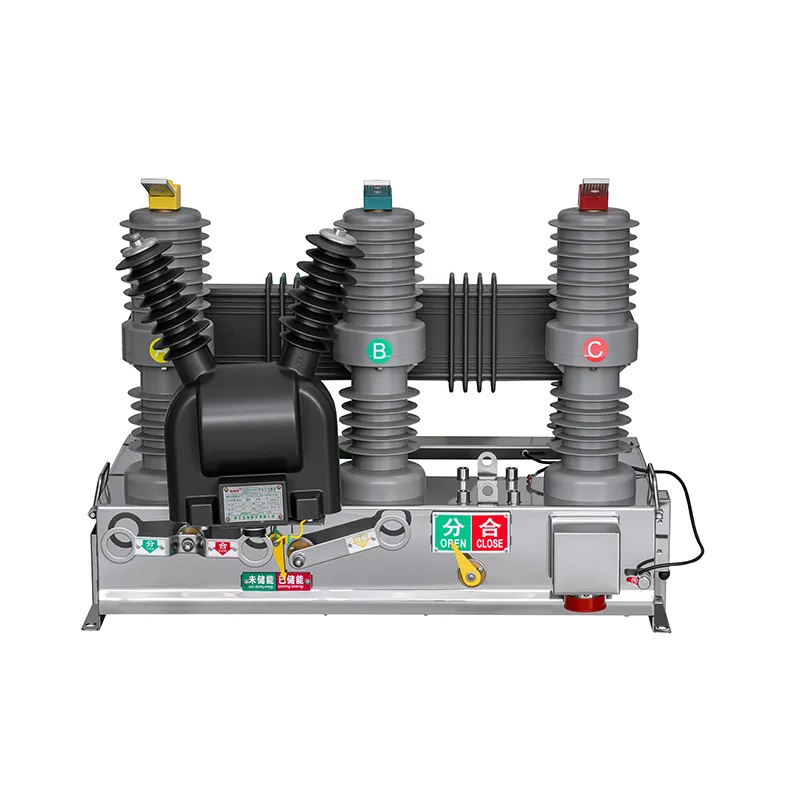

The Fully Integrated Primary & Secondary Pole-Mounted Vacuum Circuit Breaker combines the primary switching components (such as contacts, interrupter, and insulation) with secondary devices (such as protection, measurement, and communication modules) into a single intelligent unit.

It is mainly used in overhead distribution networks for sectionalizing, interconnection, and protection, enabling fast fault isolation and improved supply reliability and automation.

2. Key Features

Highly Integrated – Reduces wiring and interfaces between primary and secondary devices, improving reliability and reducing failure rates.

Smart Functions – Offers protection, measurement, control, and communication, supporting remote monitoring, fault location, and auto-reclosing.

High Reliability – Excellent arc-extinguishing, insulation, and mechanical performance, suitable for harsh outdoor conditions.

Easy Installation & Maintenance – Compact, lightweight design, self-diagnosis, and fault warning functions to lower maintenance costs.

3. Technical Specifications

Rated Voltage: Typically 10kV, 20kV (customizable)

Rated Current: 630A, 1250A

Rated Short-Circuit Breaking Current: 12.5kA, 16kA, 20kA

Rated Short-Circuit Making Current: ~2.5× breaking current

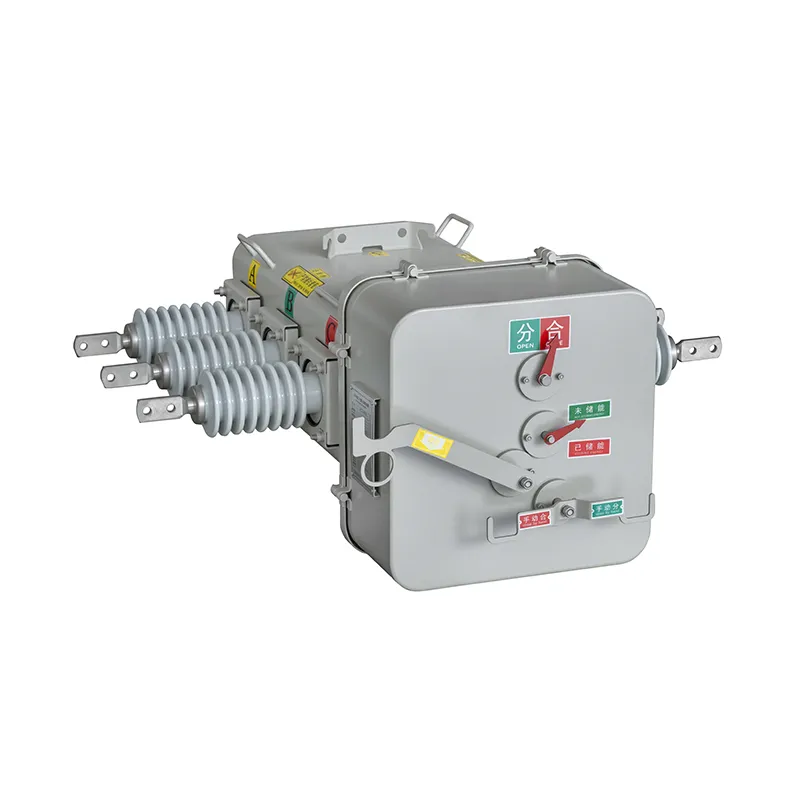

Operating Mechanism: Spring or permanent magnet type

Mechanical Life: ≥10,000 operations

Protection Level: IP65 or higher

Communication Interfaces: RS485, Ethernet, wireless options

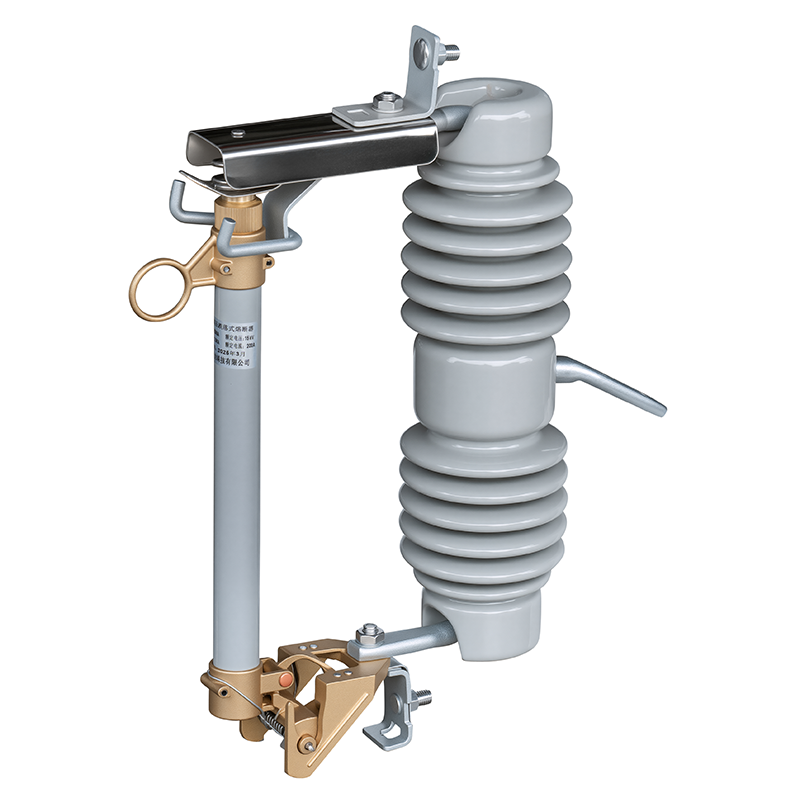

4. Structure

Primary Equipment: Switch body, contacts, interrupter (vacuum or SF₆), insulating supports, current transformers.

Secondary Equipment: Protection & control unit, communication module, power supply module.

5. Installation & Commissioning

Install in a dry, elevated, and well-ventilated location.

Mount securely on the pole structure, ensuring proper alignment.

Connect primary circuits and secondary wiring as per diagrams.

Perform insulation resistance and withstand voltage tests, protection function checks, communication setup, and open/close operation tests.

6. Operation

Manual: Via handle on-site (with power off).

Remote: Through SCADA or automation master station.

Auto-Reclosing: Configurable delay for transient fault recovery.

7. Maintenance & Troubleshooting

Routine: Clean surfaces, tighten bolts, check indicators.

Periodic: Inspect and test both primary and secondary components every 1–2 years.

Troubleshooting: Address issues in switching, protection, or communication by inspecting mechanisms, wiring, and settings.

8. Transport & Storage

Use proper lifting and protection during transport.

Store upright in dry, ventilated areas with controlled temperature/humidity.

Request a Quote Now

Our team will get back to you within 24 hours.