2026 Cost of Replacing Electric Fuse Box Full Price Guide

2026 cost of replacing electric fuse box with breaker panel average prices factors tips and regional price ranges

Read More

Switchgear is a crucial part of electrical power systems, and understanding the differences between high voltage (HV), medium voltage (MV), and low voltage (LV) switchgear helps in selecting the right equipment for your project. Here’s a clear breakdown:

| Feature | Low Voltage (LV) | Medium Voltage (MV) | High Voltage (HV) |

|---|---|---|---|

| Voltage Range | Up to 1 kV | 1 kV – 36 kV | Above 36 kV |

| Typical Applications | Commercial buildings, small industrial plants | Larger industrial sites, substations | Utilities, power transmission, large industrial plants |

| Switchgear Size | Compact, often metal-enclosed | Moderate size, metal-clad or metal-enclosed | Large, air- or gas-insulated; bulky or compact GIS |

| Component Complexity | Simple circuit breakers, fuses, contactors | Circuit breakers, disconnectors, relays | Advanced breakers (SF6, vacuum), complex protection systems |

| Insulation Type | Air or vacuum | Air, vacuum, or SF6 | Mostly SF6 gas or eco-friendly gases, air-insulated |

| Testing Standards | IEC 60947 series | IEC 62271-200 (partial) | IEC 62271 series, IEEE C37 |

| Cost Range | Lowest | Moderate | Highest |

Choosing the right switchgear depends on your system’s voltage level, application, safety requirements, and available space. Understanding these differences is critical for effective power system design.

Air-insulated switchgear (AIS) is the traditional type of high voltage switchgear, where the electrical components are separated by air. Its design is generally straightforward, consisting of metal-clad compartments, busbars, circuit breakers, and disconnectors arranged in a modular fashion. AIS is relatively easy to install, inspect, and maintain due to its open structure.

While SF6 gas has been the industry standard due to its excellent insulation and arc-quenching properties, it is a potent greenhouse gas. Emerging alternatives like g3 (Green Gas for Grid), clean air mixtures, and fluoronitrile-based gases offer significant environmental benefits, reducing the global warming potential without compromising performance.

GIS drastically cuts substation size requirements, making it perfect for urban environments, underground installations, and places where land is at a premium. The compact design also offers better protection against weather, dust, and humidity.

While GIS has a higher initial CAPEX due to its complex design and gas handling, it often leads to lower lifecycle costs with reduced maintenance, longer service life, and space savings.

Current GIS innovations focus on eco-friendly gas mixtures, digital monitoring integration, and hybrid designs. Hybrid switchgear combines AIS and GIS benefits to optimize cost, footprint, and performance.

Emerging solutions include hybrid switchgear that uses GIS for critical components and AIS for others, plus advancements in eco-gas filling systems and smart control technologies to enhance reliability and sustainability.

For those interested in detailed components like high-voltage isolators used in these systems, exploring high voltage isolator switches can provide useful insights into the design variations within AIS and GIS setups.

High voltage switchgear includes several essential parts that work together to ensure safe and reliable power distribution. Here’s a straightforward breakdown:

Whether you’re working on air-insulated switchgear (AIS) or gas-insulated switchgear (GIS), understanding these core components helps ensure you select and maintain the right equipment for your high voltage substation needs.

High voltage switchgear must comply with strict international standards to ensure reliability, safety, and interoperability. The IEC 62271 series is the cornerstone, covering critical aspects like electrical characteristics (IEC 62271-100), metal-enclosed switchgear (IEC 62271-200), and low-frequency switching devices (IEC 62271-203). These standards define performance requirements for ratings, insulation, and testing procedures.

In parallel, IEEE C37 standards provide guidelines widely recognized in North America, focusing on testing, design, and maintenance of high voltage equipment. Both IEC and IEEE standards help manufacturers and users align on quality and safety benchmarks.

Testing is split into type-testing and routine testing. Type-testing validates the design and performance of a switchgear model before mass production, while routine testing ensures each unit meets those specifications. This layered process guarantees consistency in real-world applications.

Given the increasingly varied installation sites, seismic and environmental qualifications have become essential. Switchgear must be tested for earthquake resistance, extreme temperatures, humidity, and pollution levels to maintain operational integrity, especially in regions prone to harsh conditions.

For integrating protection and measurement devices, switching components like current transformers and voltage transformers play a vital role. High-quality transformers such as the current transformer and voltage transformer compliant with these standards further enhance system reliability.

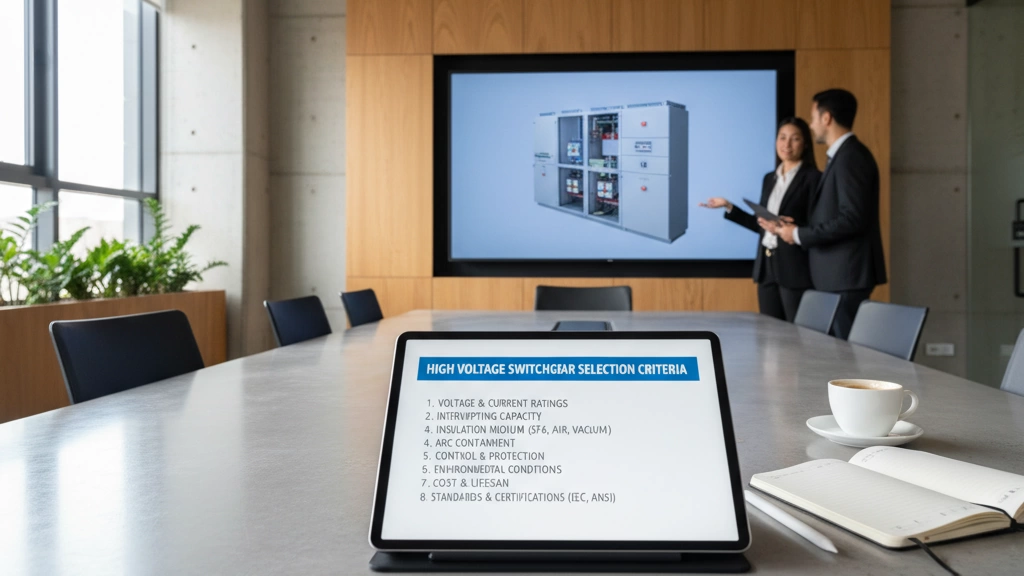

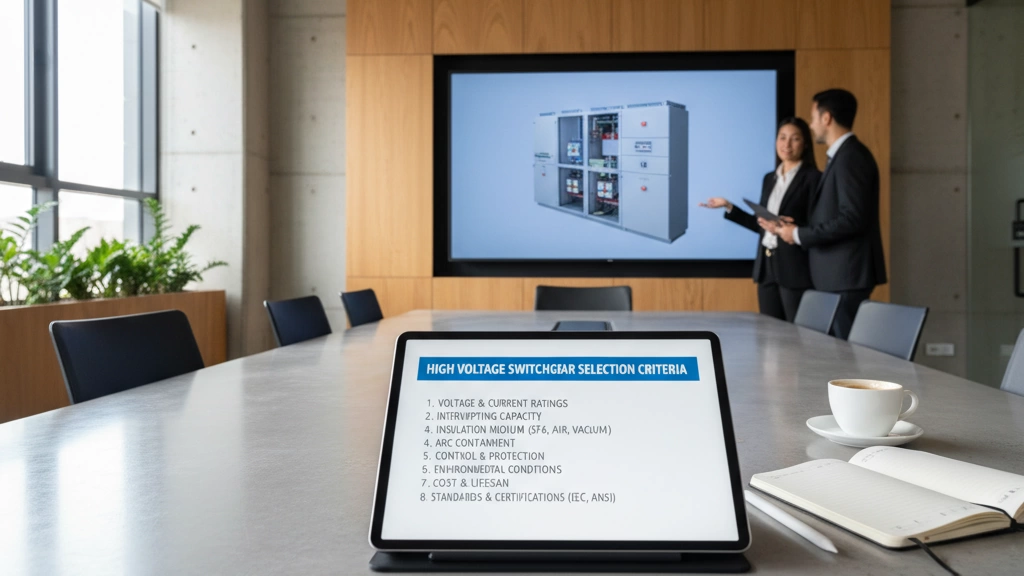

Choosing the right high voltage switchgear starts with understanding the key technical specs like rated voltage, short-circuit current capacity, and Basic Insulation Level (BIL). These define how much electrical stress the switchgear can handle safely.

Environmental factors are just as important. You need to consider temperature extremes, altitude effects, and pollution levels where the equipment will operate. Harsh or corrosive environments demand more robust designs to ensure reliability.

Footprint and weight also matter, especially in urban or space-constrained installations. Compact switchgear solutions can reduce site costs and ease installation challenges.

From a financial perspective, it’s essential to evaluate the total lifecycle cost—not just upfront capital expenses (CAPEX) but also ongoing operational costs (OPEX), including maintenance and energy use.

With growing environmental concerns, SF6-free and eco-friendly designs are gaining ground. Many customers now require sustainability features that align with local regulations and corporate responsibility goals.

Lastly, digital substation readiness is critical. Switchgear compatible with IEC 61850 protocols and equipped for remote monitoring and control supports smarter grid management and future-proofs your investment.

For more on tailored switchgear solutions, explore our range of high voltage products.

High voltage switchgear must prioritize safety to protect both people and equipment. Key safety features focus on managing arc flashes—powerful electrical explosions that pose severe risks.

| Safety Feature | Benefit |

|---|---|

| Internal Arc Classification | Limits damage and improves personnel safety |

| Pressure Relief Systems | Prevents equipment rupture |

| Fast-Acting Protection | Cuts fault duration |

| Remote Monitoring | Enhances safety, lowers risk |

Advanced safety in high voltage switchgear is not just about protection—it’s about preventing incidents before they happen, ultimately supporting safer power systems. For more info on the latest switchgear safety innovations, you can explore our detailed blog on high voltage equipment safety.

Getting high voltage switchgear installed, tested, and commissioned right is crucial for safe and efficient operation. Here’s what you need to keep in mind:

Proper installation and testing set the stage for safe, reliable operation of your high voltage switchgear and help avoid costly downtime later on.

Keeping high voltage switchgear running smoothly means having the right operation and maintenance plan. The two main approaches are preventive and predictive maintenance.

High voltage switchgear typically lasts 20-40 years, depending on operating conditions and maintenance quality. When aging or technology updates are needed, refurbishment options include:

Regular maintenance combined with smart condition monitoring extends switchgear life, improves safety, and cuts overall costs.

The future of high voltage switchgear is shaping up around a few key trends that are set to transform the industry by 2035.

SF6 gas, widely used in gas-insulated switchgear (GIS), faces growing restrictions due to its high global warming potential. Many countries and regions are moving towards strict regulations or outright bans, pushing manufacturers and users to adopt eco-friendly switchgear solutions. Alternatives like g3 gas, clean air, and fluoronitrile are gaining traction, offering comparable performance without the environmental impact.

Digitalisation is changing how switchgear operates and is maintained. Smart switchgear equipped with IoT sensors enables real-time monitoring, predictive maintenance, and remote control. This reduces downtime and cuts operational costs, making digital substation readiness a must-have feature for new installations.

Flexibility and fast deployment are driving demand for modular switchgear. These systems allow easy upgrades and expansions, ideal for evolving grid requirements. Plug-and-play designs simplify installation and reduce footprint, crucial for urban and space-constrained sites.

With the growth of renewable energy and HVDC transmission, switchgear applications are pushing beyond traditional limits. Expect to see more 800 kV+ DC switchgear solutions hitting the market, designed for ultra-high voltage levels and reliable performance in complex grid setups.

These trends ensure that high voltage switchgear not only keeps pace with today’s energy demands but is also ready for a cleaner, smarter, and more flexible power future.

The global high voltage switchgear market in 2025 features several leading manufacturers known for quality, innovation, and reliability. Companies focus on delivering both Air-Insulated Switchgear (AIS) and Gas-Insulated Switchgear (GIS) across voltage ratings from 72.5 kV up to 550 kV, meeting diverse customer needs worldwide.

cnsovio stands out as a trusted name for high voltage switchgear solutions. With years of experience, the company combines cutting-edge technology and solid engineering to provide reliable GIS and AIS products. Their portfolio covers a wide voltage range, especially from 72.5 to 550 kV, suitable for both utility and industrial projects.

Why engineers prefer cnsovio:

For customers looking for dependable high voltage switchgear in 2025, cnsovio offers a balance of innovation, compliance, and local market expertise that makes it a top choice in GIS and AIS equipment.